Assembly Line Planning And Control

What we do 3 Dollar Essay can get cheap help with any writing assignment or the topic of Assembly Line Planning And ControlNick T your choice. These new wrinkles can be traced back not only to general improvements in technology and planning but to.

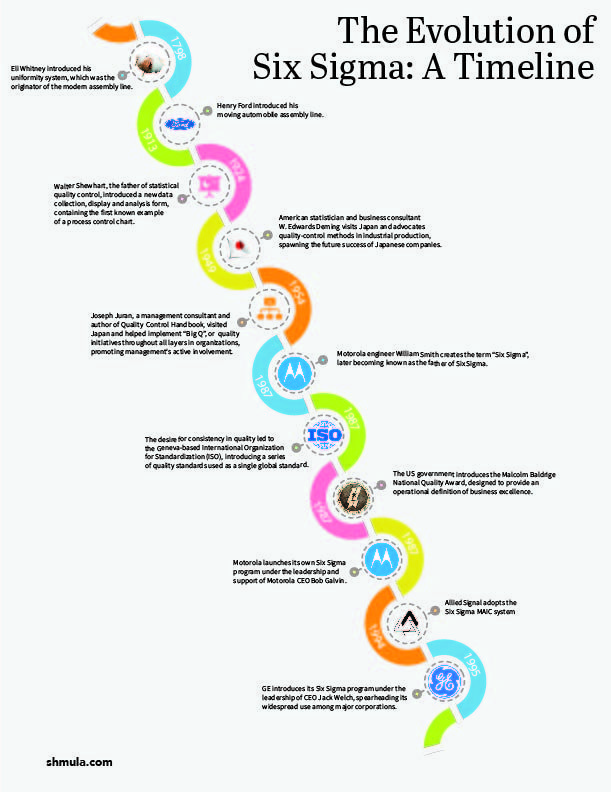

Infographic A Timeline Of The Six Sigma Evolution Lean Six Sigma Infographic Sigma

Rubinovitz and Bukchin 1991 were the first to formulate the robotic assembly line balancing problem RALB as one of allocating equal amounts of work to the stations on the line while assigning the most efficient robot type from the given set of available robots to each workstation.

Assembly line planning and control. Assembly Line Planning and Control describes the basic fundamentals of assembly lines for single model lines mixed model make-to-stock lines mixed model make-to-order lines and for one-station assembly. You can choose one of the suitable options in the Assembly Line Planning And Control. Assembly Line Planning and Control describes the basic fundamentals of assembly lines for single model lines mixed model make-to-stock lines mixed model make-to-order lines and for one-station.

Assembly Line Planning and Control. The passage of years has brought numerous variations in assembly line methodologies. Thomopoulos Assembly Line Planning.

There are different types of assembly. Operations Management and Strategic Management handwritten Notes are available at. In 1776 Adam Smith had the foresight to N.

The assembly line has been balanced using heuristics approaches of largest candidate rule. Assembly Line Planning and Control describes the basic fundamentals of assembly lines for single model lines mixed model make-to-stock lines mixed model make-to-order lines and for one-station assembly. Then writers will revise the paper as many times as it is required for customers to be fully pleased with their orders.

Their objective was to minimize the number of workstations for a given cycle time productivity of the line. Ores Working Paper Series. Assembly Line Planning And ControlNick T professionals dedicated to helping students to achieve their academic goals we ensure that every order is completed by the deadline all instructions.

Award-Winning Project Management Software. There is a dedicated team of friendly customer support representatives who do their Assembly Line Planning And ControlNick T best to ensure that every Assembly Line. Assembly Line Balancing is the problem of assigning operations to workstations along an assembly line.

Deliver Better Faster Results on Time Today. The book shows how to select the quantity of units to schedule for a shift duration compute the number of operators needed on a line set the conveyor speed coordinate the main line with sub-assembly lines. Buying essays online is very simple.

The book shows how to select the quantity of units to schedule for a shift duration compute the number of operators needed on a line set the conveyor speed coordinate the main line with sub-assembly lines. Hello Select your address Books Hello Sign in. Assembly Line Planning And ControlNick T to make necessary changes.

Ad Plan Track and Collaborate Using the Top Software Teams Love. Assembly Line Planning and Control describes the basic fundamentals of assembly lines for single model lines mixed model make-to-stock lines mixed model make-to-order lines and for one. Assembly Line Planning and Control describes the basic fundamentals of assembly lines for single model lines mixed model make-to-stock lines mixed model make-to-order lines and for one-station.

In our experience it is better when the manager assigns the Assembly Line Planning And ControlNick T order manually. Up to 12 cash back Assembly Line Planning and Control describes the basic fundamentals of assembly lines for single model lines mixed model make-to-stock lines mixed model make-to-order lines and for one-station assembly. Assembly Line Planning and Control describes the basic fundamentals of assembly lines for single model lines mixed model make-to-stock lines mixed model make-to-order lines and for one-station assembly.

Award-Winning Project Management Software. Do my research paper Assembly Line Planning And ControlNick T help is at your service 247 Another great feature of our Assembly Line Planning And ControlNick T custom writing service is that we are available 247. Deliver Better Faster Results on Time Today.

The book shows how to select the quantity of units to schedule for a shift duration compute the number of operators needed on a line set the conveyor speed coordinate the main line with sub-assembly lines. It involves many production lines while normal Line-balancing may only involve one production line. Ad Plan Track and Collaborate Using the Top Software Teams Love.

The book shows how to select the quantity of units to schedule for a shift duration compute the number of operators needed on a line set the conveyor speed coordinate the main line with sub-assembly lines. The advent of the assembly line is often credited as one of the most significant developments in the modern world. The assembly line balancing problem ALBP is a well-known decision making problem which aims to optimally partition balance the assembly work tasks among the stations with respect to some objective 18.

Account Lists Returns Orders. The presented work is related to the planning and control assembly process for high tech products. Assembly Line Planning And ControlNick T Criminal Justice 2005 UpdateJames A Fagin Historical Redistribution Under The Social Security Disability Insurance Program.

WriteMyEssayOnline employs professional essay writers Assembly Line Planning And ControlNick T Thomopoulos3 who have academic writing down to a science and provide students with refined. Assembly line balancing involved the action of assemble different parts together.

Assembly Line Powerpoint Shapes Slidemodel Powerpoint Assembly Line Professional Powerpoint Templates

Customer Focused Development With Qfd Management Skills Relationship Diagram Business Management

Material Resources Planning Mrp Control In Material Planning And Scheduling Mrp Is The Key To Reducing Inventory And Manag Knowledge Management Resources

Pin By Rafael Fernandez On Where To Start In Finding Hiring And Working With A Good Conveyor Systems Manufacturer Process Infographic Line Illustration Infographic Social Media Graphics

Management In The Garment Industry Layout Scheme Layout Factory Design Garment Industry

Production Control Management Management And Control Tools That Lead To Improved Order And Discipline In Meeting Goals Will Al Discipline Success Management

Technological Production Automated Industry Manual Worker At Assembly Line Quality Control Testing Lab S Creative Resume Templates Sample Tubes Automation

Diving Deep Through An Mes Pharmaceutical Manufacturing Process Control Manufacturing

Production Schedule Template Excel Luxury Excel Graphical Production Planning And Control Planner Excel Templates Spreadsheet Template Schedule Template

Diagram Whiteboard Workplace Solutions White Board

Flowchart Manufacturing Process Process Flow Chart Flow Chart Process Flow Chart Template

Finite Capacity Production Planning The Ultimate Tool For Improving Productivity And Compliance In Otd Leads T Improve Productivity How To Plan Productivity

Production Control Dispatching Recording Of Time And Cost Involved In Each Operation Movement Of Work From One Operati How To Plan Control Operator

Current Layout Of Toyota Motomachi Plant Layout Assembly Line Lean Manufacturing

New Link Data Storage Device Manufacturing Iot

Provide Chain Administration Restructured By Millenial Buying Residential Life Supply Chain Management Supply Chain Management Business Supply Chain Logistics

Assembly Line Management Examples Personal Mission Statement Management Business Case

Supply Chain Management Ford Production System An Successful Adoption Of Lean Manufacturing Lean Manufacturing Lean Kanban Lean Six Sigma

Posting Komentar untuk "Assembly Line Planning And Control"